Lean six sigma in the manufacturing and service sector

Lean Six Sigma has emerged as a powerful methodology that can be applied in the manufacturing and service sectors to achieve these objectives. We will explore the world of Lean Six Sigma, its applications in various industries, and how companies like Burraq Engineering Solutions leverage it to drive excellence.

Understanding Lean Six Sigma

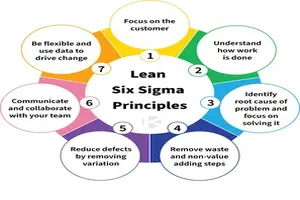

Lean Six Sigma is a data-driven approach to process improvement that combines two powerful methodologies: Lean and Six Sigma. Let’s delve into each of these components to understand the essence of Lean Six Sigma.

Lean Principles

- Eliminating Waste: Lean principles focus on identifying and eliminating waste in processes, such as overproduction, excess inventory, and unnecessary motion. This reduction in waste leads to increased efficiency and lower costs.

- Continuous Flow: Lean emphasizes creating a seamless and continuous flow of products or services, ensuring that work moves swiftly through the system.

- Pull Systems: Lean encourages a pull system, where work is initiated based on actual customer demand rather than pushing products or services into the system, which can lead to overproduction.

Six Sigma Methodology

- Data-Driven Decision-Making: Six Sigma uses data analysis to make informed decisions and improvements. It employs statistical tools to measure and reduce process variation.

- DMAIC Framework: Six Sigma uses the DMAIC (Define, Measure, Analyze, Improve, Control) framework to systematically tackle process issues, leading to tangible results and sustainable improvements.

Lean Six Sigma in Manufacturing

Lean Six Sigma has found a natural home in the manufacturing industry, where efficiency and quality are paramount. Here’s how it’s making an impact:

1. Process Efficiency

Manufacturers use Lean Six Sigma to streamline their production processes, eliminating bottlenecks and reducing lead times. By implementing Lean principles, they ensure that resources are used efficiently, which leads to cost savings and increased productivity.

2. Quality Improvement

In manufacturing, defects can be costly and damaging to a company’s reputation. Six Sigma tools and methodologies help identify the root causes of defects and reduce their occurrence, leading to higher-quality products.

3. Cost Reduction

Lean Six Sigma helps manufacturers cut costs by optimizing their supply chain, reducing waste, and enhancing production processes. This directly impacts the bottom line, making companies more competitive.

Lean Six Sigma in the Service Sector

Lean Six Sigma is not limited to manufacturing. It has also gained significant traction in the service sector, where providing high-quality, efficient services is crucial. Here’s how it’s transforming the service industry:

1. Improved Customer Experience

In the service sector, customer satisfaction is paramount. Lean Six Sigma tools enable service providers to identify and address issues directly impacting the customer experience. This results in happier customers and increased loyalty.

2. Reduced Service Delivery Times

Whether in healthcare, banking, or logistics, reducing service delivery times is a common goal. Lean principles help service organizations eliminate unnecessary steps and delays, ensuring faster service delivery.

3. Cost Efficiency

Service companies use Lean Six Sigma to optimize their internal processes, reduce costs, and improve their bottom line. By identifying and eliminating waste, they can provide cost-effective services without compromising quality.

Leveraging Lean Six Sigma

One company that has harnessed the power of Lean Six Sigma in both the manufacturing and service sectors is Burraq Engineering Solutions. As a leading provider of engineering and technical solutions, they have integrated Lean Six Sigma into their operations to achieve exceptional results.

Manufacturing Excellence

Burraq Engineering Solutions has implemented Lean Six Sigma principles to enhance its manufacturing processes. By reducing waste, optimizing production flows, and focusing on quality improvement, they have achieved higher efficiency and reduced costs, allowing them to deliver top-quality products to their clients.

Service Excellence

In the service sector, Burraq Engineering Solutions has embraced Lean Six Sigma to provide exceptional technical support and service to its clients. By implementing Lean principles and Six Sigma methodologies, they have streamlined their service delivery, reduced response times, and improved customer satisfaction.

FAQs About Lean Six Sigma

Q1: Is Lean Six Sigma only for large companies?

No, Lean Six Sigma is a versatile methodology that can be adapted to the needs of organizations of all sizes. Small and medium-sized businesses can benefit from Lean Six Sigma’s principles and tools.

Q2: How long does it take to see results with Lean Six Sigma?

The timeline for seeing results with Lean Six Sigma varies depending on the complexity of the project and the commitment of the organization. In some cases, improvements can be realized in weeks, while larger projects may take several months.

Q3: Can Lean Six Sigma be applied to non-manufacturing industries?

Lean Six Sigma is not limited to manufacturing. It has been successfully applied in various service industries, healthcare, finance, and more.

Q4: What training is required to implement Lean Six Sigma?

Training is essential for successful Lean Six Sigma implementation. There are various certification programs and training courses available, ranging from White Belt to Black Belt levels, to equip employees with the necessary skills and knowledge.

3 Reasons Why Manufacturing Training Is Essential

Keeps employees safe while on the job

Manufacturing training guarantees that employees understand how to safely perform the important functions of their job. This not only keeps the individual safe on the workplace, but it also protects their coworkers.

Immersive learning technologies, such as virtual reality (VR) or augmented reality (AR), put factory employees in a learning environment where they may practice operating and repairing equipment without jeopardizing their safety. This ensures they are prepared for the task and can carry out processes with confidence.

Improves Employee and Production Efficiency

Employee training can lead to increased staff and production efficiencies for organizations. Employees who receive comprehensive job-related training are less prone to make mistakes that reduce their efficiency and production.

Manufacturing staff receive process and equipment training to equip them with the information they need to complete procedures efficiently in their employment. Manufacturing businesses can enhance output and better satisfy industry demands with a more efficient staff.

Increases Employee Retention and Satisfaction

Manufacturing Training for Satisfied Workers Within the first year, organizations lose 25% of all new employees. Training, on the other hand, can reduce turnover by enhancing staff retention and job satisfaction. Workers will be more inclined to stay with a company that promotes their development through training possibilities.

Training programs that begin on Day 1 and continue throughout an employee’s lifecycle aid in the development of long-term employees who support the growth of your firm. Organizations with lower turnover rates not only save money, but also build a more tenured staff.

BES Institute’s Manufacturing and service sector Certification courses are designed to provide you with the skills and information needed to improve your quality management procedures and the effect you have within your business.

- Understanding LEAN methodology concepts

- Learning the six sigma concepts and tools

- DMAIC process stages

- Finding and assessing the bottlenecks

- Mapping the customer value stream

- Grasping the 7 types of waste

- The Define Phase

- The Measure Phase

- Define/Measure (Understanding the Current State)

- Project Definition, Project Charter

- Values Stream Mapping (VSM), Spaghetti Diagram

- Normality, Stability, Capability Analyses

- Analyze (Understanding Variation and Causal Factors)

- Analysis Plan & Hypothesis Testing

- T-Test, Chi-Square, Correlation, Regression, Equal Variances

- The Improve Phase

- Improve/Control (Generating Breakthrough Improvements)

- Mistake Proofing

- Kaizen

- Single Piece Flow

- Cost/Benefit Analysis

- Understanding key LEAN methods used for process improvement

- Implementing LEAN tools to decrease process waste

- Recognizing the elements of continuous improvement

- Bringing about measurable improvements in customer satisfaction,

- product quality and profitability

Lean six sigma in the manufacturing and service sector

- Rs 40,000/-

- Course Duration 1 Month

- Online Session

- On Campus Lecture + Practical

- Video Lecture Available

- Urdu & English

- 24/7 Support

- Fee: 40,000

- Duration: 1 Month

- Timing: 9AM-11AM, 11AM-1PM, 1PM-3PM, 3PM-5PM, 5PM-7PM, 7PM-9PM